High Pressure Food Processing Equipment Investment Casting, For

A major consideration during the design of a food processing facility, especially a ready-to-eat (RTE) or one that is even close to being a RTE product, is the establishment of positive air pressure zones.. This keeps the ductwork out of the processing areas and provides access to the ducts without interfering with the processing operation.

How to clean your own air ducts I had no idea you can DIY this but

Ducting.com offers a large selection of food grade hoses and equipment that meet the demands of high-volume food processing, transfer, and collection. Need Help? Call (844) 782-2374.. The "Thermoplastic Flex White" hose is another material handling FDA-approved duct that is great for food processing plants and manufacturers due to its.

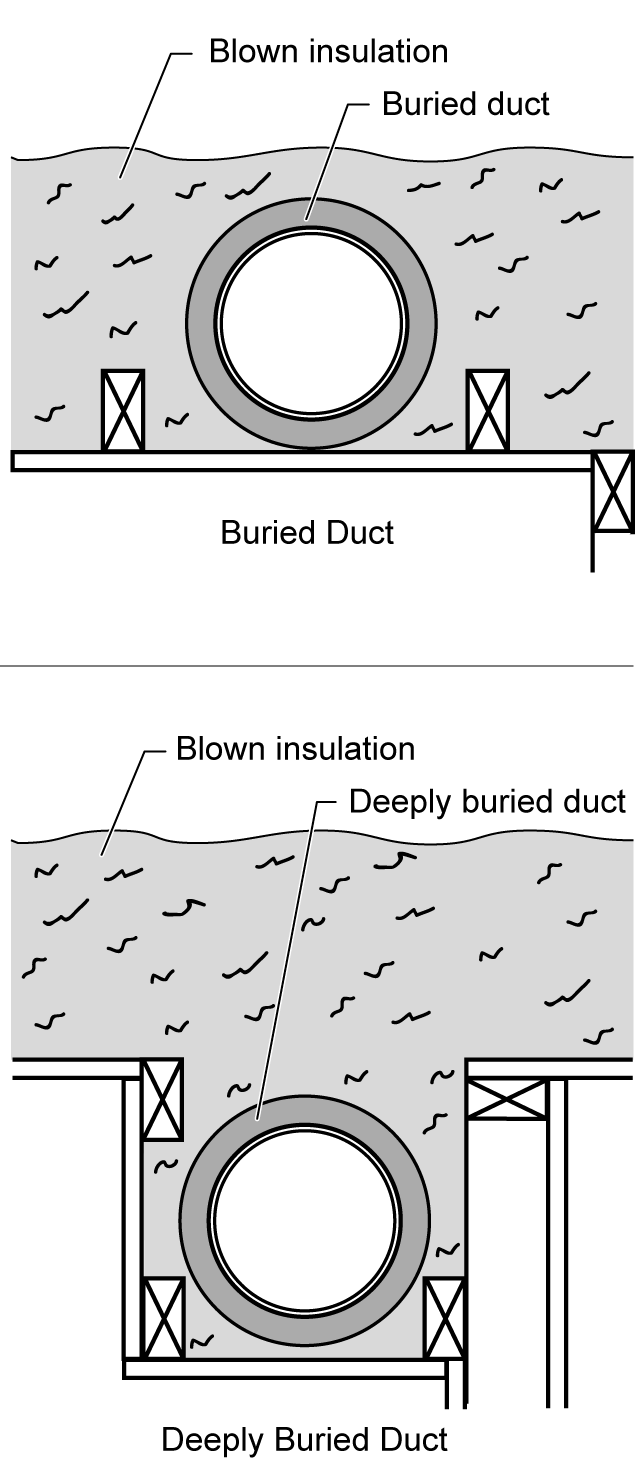

4.4 Air Distribution System Ducts, Plenums, and Fans

Specifying a Fabric Duct System. Fabric Duct Systems has TWO types of duct fabric: Polyester and Polyethylene.. This low velocity is excellent for food processing plants, swimming pools, ice arenas and other applications where low velocity air greatly retards evaporation as in a packing house or swimming pool. There are many other.

Free photo Air Conditioning Ducting Air, Conditioning, Duct Free

In the food processing industry, maintaining the highest product quality is paramount. Therefore, it is essential to have a high-quality, fabric-based air distribution system that guarantees hygienic operation, eliminates drafts and improves the well-being and comfort of employees.. Duct system is custom engineered to create the ideal fit.

Food Grade Silicone Rubber Stockwell Elastomerics

Common food dust collection challenges include cereal ingredients, spices, raw grains, egg shell dust, flours, corn starches, sugars and other sticky materials. If a facility produces both free-from foods and standard food products for a more general consumer audience, industrial dust collection is the first line of defense in controlling cross.

Unit Operation In Food Processing Earle Pdf

The food processing industry is divided into the consumption, catering, & supply of food products. Energy efficiency, hygiene, & reduction of waste.. Duct design is a crucial element of the HVAC (heating, ventilation & air conditioning) system. Preferably, it should be installed outside manufacturing areas & be easy to access for cleaning.

5 Ways to Keep Your Indoor Air Clean AZ Air Duct

Dust collection systems work by pulling food processing dust and other contaminated air through a hood, into a ducting system, and into a dust collector where it is filtered and cleaned. Nordfab ductwork has been used in many different food processing applications, including: • Baked goods manufacturing. • Powdered milk. • Nutraceuticals.

How to Check Your Ducts for Leaks Blog

This article will focus on key hygienic evaluation points of an air-handling unit (AHU) and the associated ductwork supplying air to rooms where exposed food products are processed. These key points include risk assessment and verification, hygienic design of AHUs and the associated ductwork, and several important food safety and quality.

a woman in a red top holding her hand to her nose with the words, your

Food and Beverage processing, packaging and distribution facilities are high-paced and tightly regulated operating environments. Proper ventilation and climate control in these facilities are essential to the integrity of the products and protection of the consumers. At Eldridge, we provide high-quality, practical, and cost-effective.

MPL Frp Ducts, For Industrial at Rs 130/square feet in Coimbatore ID

Currently, the food processing industry is undergoing a shift from focusing on contamination response to contamination prevention. In 2011, the FDA Food Safety Modernization Act (FSMA) was signed into law.. If you are considering investing in a hygienic air handling and hygienic duct system, it's important to consider all the options that.

Modeling plasmasphere ducts

Sanitary Design and Construction of Food Processing and Handling Facilities 4 be appropriately sealed and protected. Openings into the roof such as exhaust fans for air handling systems, ventilation ducts, and plumbing vent pipes must be sealed, and appropriately flashed and screened. Windows are discouraged in food

Not sure if you should schedule that duct cleaning appointment? If you

Dust produced during food processing can create significant safety and health hazards. Dust particles often become airborne and lead to fires and explosions.. (≤ PM10) can reach the respiratory ducts, while particles 2.5 microns or less (≤ PM2.5) can lodge deep inside the lungs. Inhalable particles with a diameter of 1.0 micron or less.

Understanding The Different Dryer Vent Pipe Types Dryer Not Heating

Learn more about how The Ingenious Air® Small Duct System works to provide an all-in-one solution for Industrial Air Conditioning. Call +44 1268 544 530 Talk to an Expert | UK: 0800 731 6352 | International: +44 1268 544530 . 0 Shopping Cart. Home; How It Works; Sectors. Office.

Clean Your Air Ducts This Fall Air Duct Cleaning

A clear advantage over the conventional fabric ducting used by our competitors, microperforations. reduce maintenance time and costs. Prihoda is the only fabric duct manufacturer to use cleanroom quality non-shedding material by default on all our products. This prevents any chance of contamination in food processing or production areas.

Preinsulated Duct FTA Group

The food processing industry as a whole produces many different types of dust. Some of the most common food processing dust types include fugitive grain dust from silo filling and grain transport; grain and flour dust from milling and grinding; corn starch and other powdered starches; dust from transporting or grinding dried nuts and legumes; dehydrated milk and egg products; sugar dust; and.

HVAC high volume air conditioning duct ducts ducting con unit units

1. Food processing and handling equipment should be designed and constructed to ensure that it can be effectively and efficiently cleaned. 2. Construction materials should be completely compatible with the product, environment, cleaning and sanitizing compounds, and cleaning and sanitizing methods.