Pure Cornstarch KESSLER'S Official

Starch or amylum is a polymeric carbohydrate consisting of numerous glucose units joined by glycosidic bonds. This polysaccharide is produced by most green plants for energy storage. Worldwide, it is the most common carbohydrate in human diets, and is contained in large amounts in staple foods such as wheat, potatoes, maize (corn), rice, and.

The many uses of cornstarch Our Communities

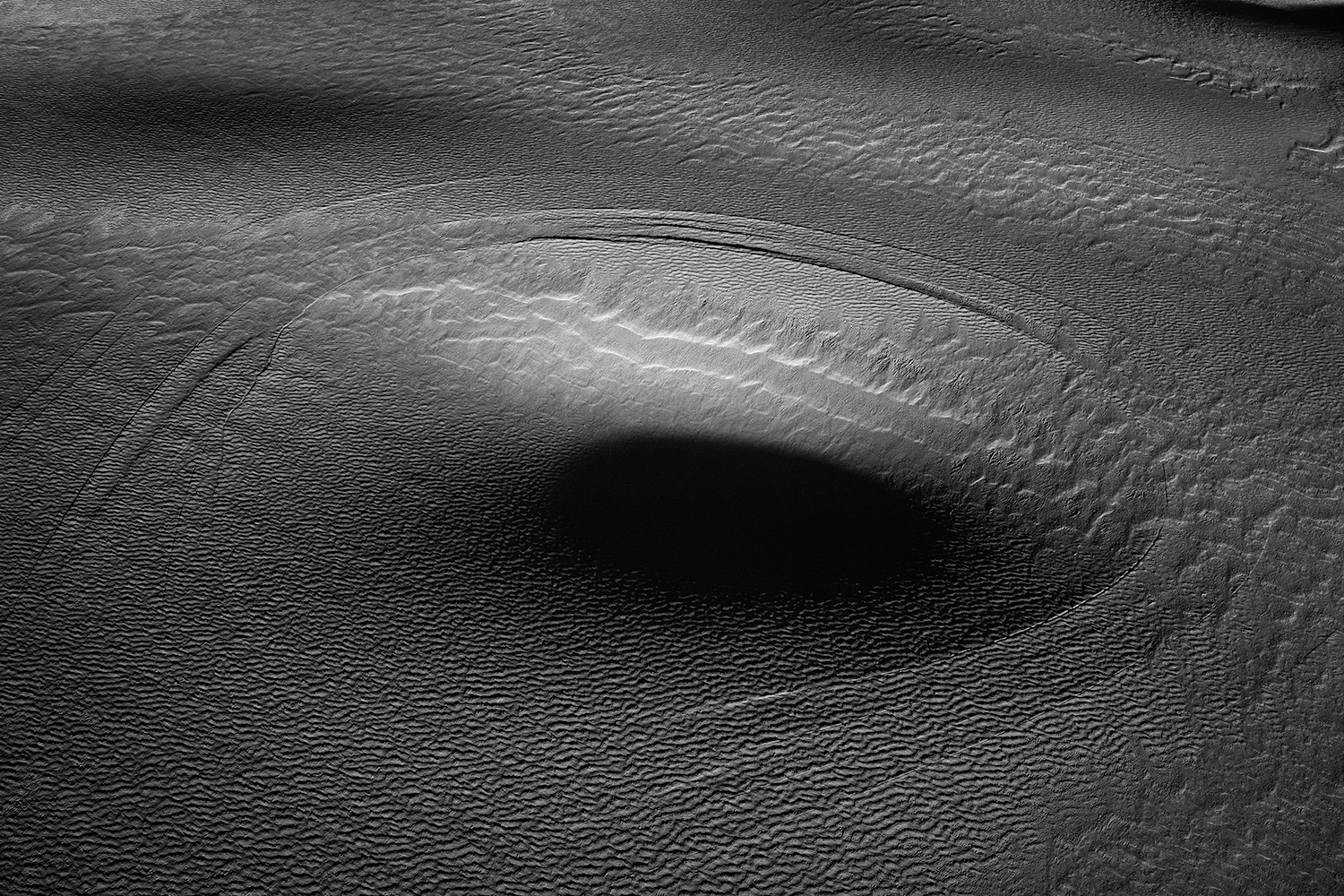

The control sample had a higher melting point than the hydrolyzed corn starch film, as indicated by the significant difference in the temperature of the first endothermic event between the two films. The atomic force microscopy (AFM) characterization of the hydrolyzed corn starch film showed intermediate surface roughness. A comparison of the.

22 Reasons Why You Need Cornstarch In Your Home

The first DSC scan of cornstarch with 11.9% MC presented a glass transition, located at 60 °C, and two endothermic peaks, located at 182 °C and 195 °C, respectively (Fig. 1).The peak at 182 °C was due to the melting of cornstarch crystals, and the one at 195 °C was due to melting of the amylose-lipid complexes.The second DSC scan of the same cornstarch had a glass transition occurring.

ASMR•Cornstarch Paste Over Cornstarch Powder YouTube

Our team of scientists has experience in all areas of research including Life Science, Material Science, Chemical Synthesis, Chromatography, Analytical and many others. Starch from corn; CAS Number: 9005-25-8; EC Number: 232-679-6; Synonyms: Corn starch,Starch from maize; Linear Formula: (C6H10O5)n; find Sigma-Aldrich-S4126 MSDS, related peer.

Cornstarch Bowl

Isotactic PVOH has a high melting point (T m = 230ºC) compared to polyethylene (T m = 117-135ºC). When corn starch was increased, the melting peak was indistinct. This indicates that the.

Cornstarch GlutenFree Sauce Thickeners POPSUGAR Fitness Photo 3

The control sample had a higher melting point than the hydrolyzed corn starch film, as indicated by the significant difference in the temperature of the first endothermic event between the two films. The atomic force microscopy (AFM) characterization of the hydrolyzed corn starch film showed intermediate surface roughness. A comparison of the.

Cornstarch 4 Division Grn Co. Packaging

Corn starch mixed in water. Cornflour, cornstarch, maize starch, or corn starch (American English) is the starch derived from corn grain. The starch is obtained from the endosperm of the kernel.Corn starch is a common food ingredient, often used to thicken sauces or soups, and to make corn syrup and other sugars. Corn starch is versatile, easily modified, and finds many uses in industry such.

(a) The solubility (SI) of cornstarch as affected by HHP at 400 MPa

INTRODUCTION ICSC CARD: 1553. Page last reviewed: October 30, 2019. Content source: National Institute for Occupational Safety and Health. Corn starch, Rice starch, Sorghum gum, α-Starch, Starch gum, Tapioca starch Fine, white, odorless powder. [Note: A carbohydrate polymer composed of 25% amylose & 75% amylpectin.]

Melting — Nº 9 QERNDU

Freezing point/melting point: decomposes Vapor pressure: 0 mmHg (approx) Flash point: Vapor density. et al.: Lung accumulations of eosinophil granulocytes after exposure to cornstarch glove powder. Eur. Respir. J. 21(4): 646-651, 2003. Newsom, S.W. and Shaw, M.: A survey of starch particle counts in the hospital environment in relation to.

Cornstarch PDF

When combined in the correct proportion, a mixture of cornstarch and water exhibits certain enigmatic properties. At the right ratio, a blend of water and cornstarch displays some mysterious qualities. It's a liquid until you throw a bowling ball on it. Then it solidifies at the point of impact and the ball bounces off.

5 Unexpected Uses for Cornstarch! (Clean My Space) YouTube

Fig. 2 presents melting points for EAB-urea, BABr-urea and 1 : 1 EABr : BABr-urea mixtures as a function of urea mole fraction. These were determined from DSC traces for each system, which are presented in the ESI† (Fig. S1). Melting points for BABr:urea are higher than those of EABr:urea at all compositions, which is attributed to stronger interactions between alkyl chains.

4 Brilliant Ways to Cook with Cornstarch Bon Appétit

Molybdenum dioxide (MoO 2), considering its near-metallic conductivity and surface plasmonic properties, is a great material for electronics, energy storage devices and biosensing.Yet to this day, room-temperature synthesis of large area MoO 2, which allows deposition on arbitrary substrates, has remained a challenge.Due to their reactive interfaces and specific solubility conditions, gallium.

Cornstarch Bowl by Xiamen Linkgreen Co., Ltd, Cornstarch Bowl from

Corn starch provides ideal characteristics for various industrial applications in the textile, food, pharmaceutical, construction fields, among others. It is composed mainly of amylose/amylopectin in different proportions and polymeric organizations. These two components of starch represent approximately ≥99% of starch by dry weight.

What is the purpose of cornstarch in baking? YouTube

Starch soluble. 9005-84-9. Soluble Starch. 9057-07-2. starch xanthate. 11116-64-6. Chemsrc provides Starch (CAS#:9005-25-8) MSDS, density, melting point, boiling point, structure, formula, molecular weight etc. Articles of Starch are included as well. >> amp version: Starch. Chemsrc provides Starch (CAS#:9005-25-8) MSDS, density, melting point.

Shaving Cream + Cornstarch = Fun I Can Teach My Child!

The Physical Property fields include properties such as vapor pressure and boiling point, as well as explosive limits and toxic exposure thresholds The information in CAMEO Chemicals comes from a variety of data sources. Note: For Vapor Density and Specific Gravity, comparing the value to 1.0 can tell you if the chemical will likely sink/rise in air or sink/float in fresh water (respectively).

Cornstarch 60 oz

The brittleness of native starch is due to the relatively high glass transition temperature and the absence of sub T g (β-transition). 133 In addition, brittleness can increase with time through the retrogradation process. 55 Furthermore, the higher melting point and lower thermal degradation temperature of starch have resulted in poor melt.